VLADIVOSTOK Grand Hotel

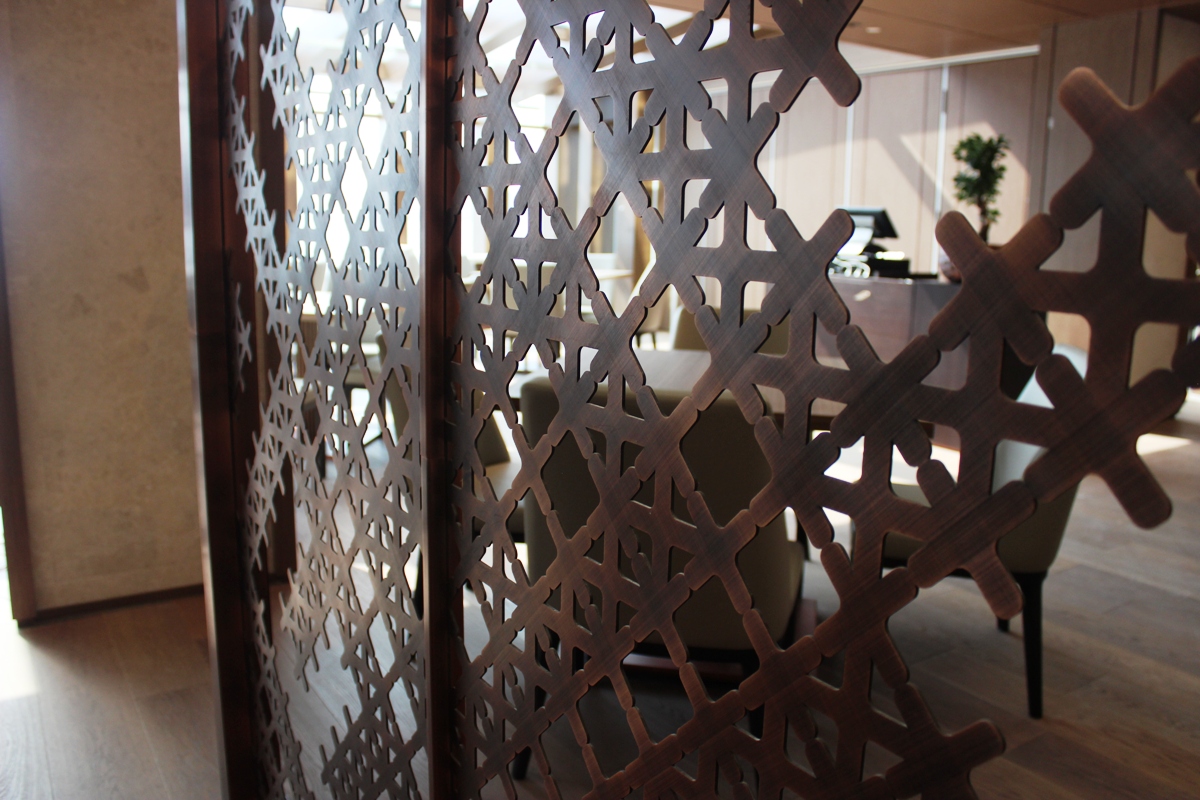

Among the countless number of projects completed by Metal Workshop, there are those that truly amaze the imagination with their filigree. And this is not only the filigree of the idea, but also the filigree of the embodiment. One of these works should definitely include the design of zoning partitions made of copper for VLADIVOSTOK Grand Hotel & SPA 5 *

We completed this order in 2021 when decorating the hotel’s flagship restaurant, AquaTerra. The project for its design was developed by the Moscow company BUROE of Ekaterina Waltz.

The main idea implemented in the interior design concept of the restaurant is a mixture of Asian and European, ancient and modern, beauty and functionality. Made in soothing colors, they embody the refined style and calm laconicism of solutions. The textures and materials used in the design clearly demonstrate coziness and discreet luxury. At the same time, Metal Workshop specialists were entrusted with a very important area of work – we created one of the style dominants of the interior – ornamented zoning partitions made of copper.

Materials and dimensions

Copper was chosen as the working material when creating partitions. On the one hand, this is an excellent solution – there are few materials that can be compared with this metal in terms of their aesthetic qualities and nobility of appearance.

However, for our specialists, this created certain problems in processing. The fact is that the final size of each zoning panel was 6m. with a copper sheet thickness of 5 mm. In addition, the partitions were actually a lace of ornament. This automatically made it impossible to create a solid partition.

Selected Solutions

Specialists of our workshop developed special frames decorated with copper sheets . Cassettes with carved patterns were inserted into these frames, as if into frames. The size of one such cassette is 2000×1000 mm. Thus, for each partition it was required to create, on average, 6 panels.

Our industry does not work with copper sheets of this size, so the workshop had to order them from abroad specifically for the project.

Surface treatment

When processing, we were forced to take into account several features of the order. Firstly, this is the thickness of the copper sheet and its parameters. Secondly, the drawing itself. The fact is that each panel is essentially a complex combination of small elements. Together they make up the ancient patterns of harvest, wealth and prosperity. Most of all, this is similar to decorative geometric ornamental cross-stitch, which our ancestors used to decorate their clothes, household items, and houses for ritual purposes.

It looks incredibly beautiful, and at the same time guaranteed significant difficulties in implementation. To ensure clear lines of the pattern, our craftsmen decided to use waterjet metal cutting. Thanks to this method, the pattern looks incredibly clear.

We also additionally processed and polished each of the numerous edges of the surface of the patterns. This is done in order to radically exclude the possibility of cutting themselves on them by visitors or service personnel. Thanks to our efforts, partitions now not only look great, but are also completely safe to use.

To give them their designed look, all copper surfaces have been sanded clean and then patinated. To prevent further oxidation of the metal and to preserve the noble effect of patinated copper for a long time, our specialists coated all metal surfaces with a special anti-corrosion colorless varnish.

After all decor elements, including the frame and decorated cassettes, were ready, we carried out a mandatory control assembly at the enterprise, methodically checked each element for possible defects, marked them, compiled assembly instructions, and then disassembled, carefully packed and sent to the final place assembly in Vladivostok.

Mounting

The final assembly and installation of partitions was also carried out by our craftsmen. This provided an unprecedented speed of work and its quality. We completed the final installation in just 2 weeks. Given the titanic amount of work and high complexity, this is an excellent result, which once again confirmed the professionalism of the people working in Metal Workshop.

Now we proudly remember this work. After all, thanks to our work, copper ornamented partitions have taken their rightful place in the decor of the hotel’s flagship restaurant. Thanks to its 24-hour operation, visitors can enjoy the sophisticated play of light on their truly aristocratic surfaces around the clock.