CHROMIUM CUBE

This story is dedicated to just one product, but its creation became a landmark for the Metal Workshop. We are talking about the art object “Chrome in the Cube”, which we created according to the project of the architectural bureau NIDO interiors. Now it can be seen in the interiors of the 12storeez boutique on the Petrograd side of St. Petersburg, where it occupies a worthy place.

Background

The boutique is located in a building that was under reconstruction at that time. In this regard, for a long time, Metal Workshop specialists could not obtain final measurements of the planned product. Therefore, in all preparatory work, we had to rely only on design calculations and a small 3D model.

Preparatory work

The customer and the architect wanted to see polished steel as the main material. Given the non-standard form of the installation, the work did not promise to be trivial. The outstanding dimensions of the art object also contributed: 2.5 x 2.5 meters with a depth of 1.5 m.

We had to first make a metal frame, which would determine the main forms and volumes of the future creation. These works were carried out in the workshops of the Metal Workshop. After the frame was ready, and we were finally able to make final measurements, it became possible to proceed with the final design.

Installation work

A number of working moments were also associated with this stage. So, given the impossibility of welding the frame on site, we had to deliver it to the boutique already assembled. Since it was not possible to carry such an oversized item through the front doors, we quickly found a way out and transported it through the window of the showcase.

Special mention deserves the site on which “”Chromium in the Cube”” was planned to be placed. It became the space under the stairs. And this means that we had to take into account not only the features of the line of the flight of stairs and floor marks, but also how the installation will ultimately fit into the space under the stairs. We have done an excellent job with this task.

Finishing work

The main challenge during the finishing work was the design material. We used hand polishing to finish the stainless steel used in the frame cladding. The number of surfaces and seams that needed to be processed was quite significant, the lines of forms were very whimsical.

Our employees had to act very carefully. Nevertheless, the final polishing process took only 10 days – an excellent result, considering all the nuances.

In addition, metal dust, which appears abundantly when polishing steel, has become a problem. Since this was in a boutique, we had to take great care to ensure that this dust did not damage the finishes that had already been installed. We solved this problem simply and effectively: for the duration of this stage of finishing work, we installed dense plastic curtains around the installation.

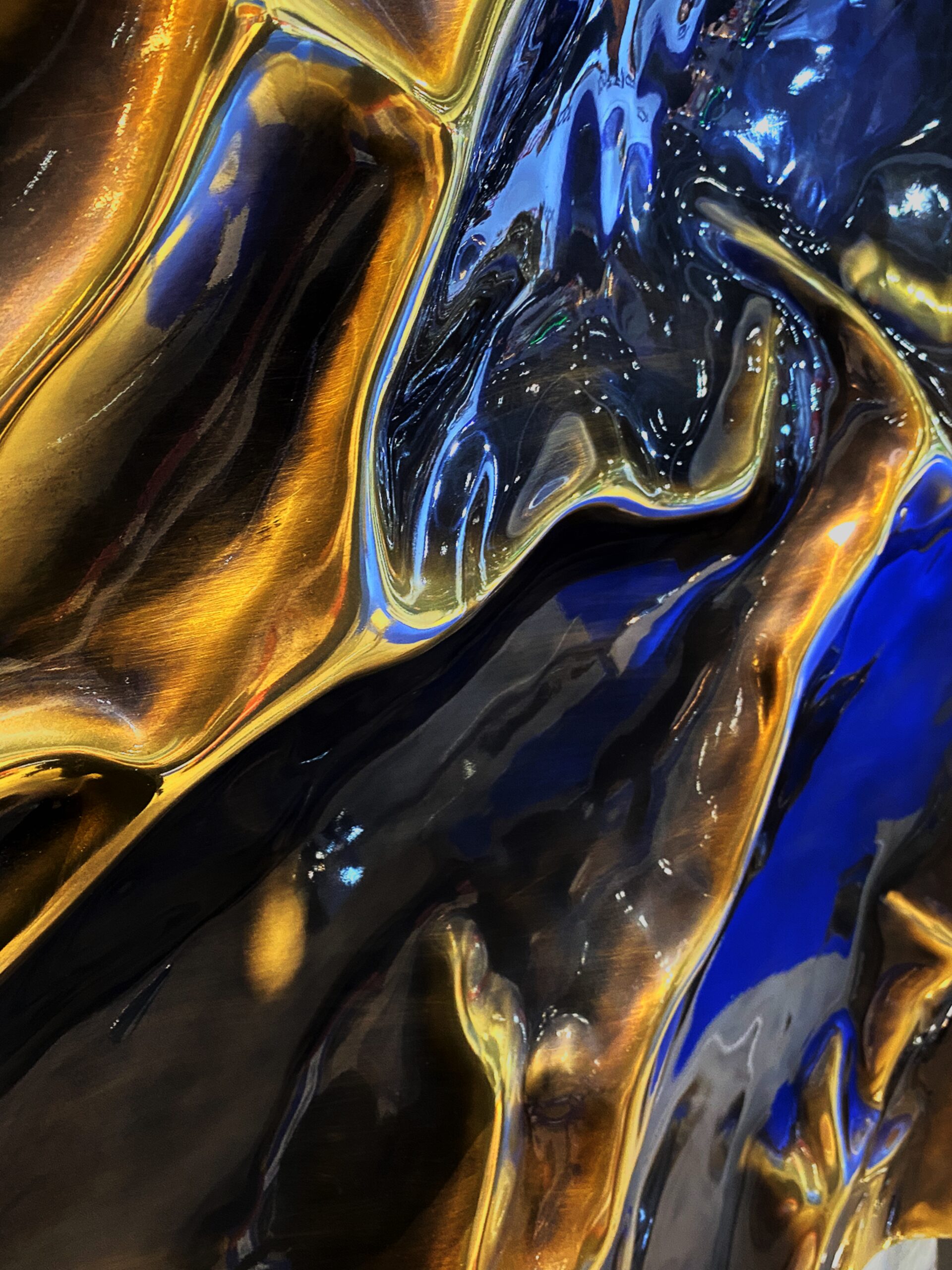

Finally, the art object was completely completed and installed in its intended place. The texture of polished steel, coupled with exquisite floating silhouettes of lines, creates the impression of a light, airy, flowing fabric. The art object gently envelops, as if framing the elements placed inside the installation, thanks to the specifics of the material it serves as a kind of reflector, and thanks to the design features, it attracts the viewer’s eye to them.

We were glad to take part in the creation of this, no doubt, a unique artifact. We wish the customer good sales and prosperity in business, and the architectural bureau – new, no less bold and sophisticated projects.”